Transforming Putaway in Warehouse Operations with Logimax

The putaway process is a critical phase in warehouse management, setting the stage for efficient storage and retrieval. Logimax’s WMS revolutionizes putaway in warehouse operations, offering directed putaway strategies that minimize errors and optimize space utilization. By intelligently guiding the placement of goods, Logimax ensures that every item finds its optimal location, reducing handling time and enhancing overall efficiency. Discover how Logimax’s putaway warehouse solutions can elevate your operations to new heights, streamline workflows, and contribute to a more agile and responsive warehouse environment.

Intelligent Directed Putaway

Logimax’s intelligent directed putaway feature guides the placement of goods in optimal locations, considering factors like product type, date rotation, size, and demand. By using advanced algorithms and real-time data, this intelligent system minimizes handling time, maximizes space utilization, and enhances overall warehouse efficiency, making it a cornerstone of a modern putaway warehouse strategy.

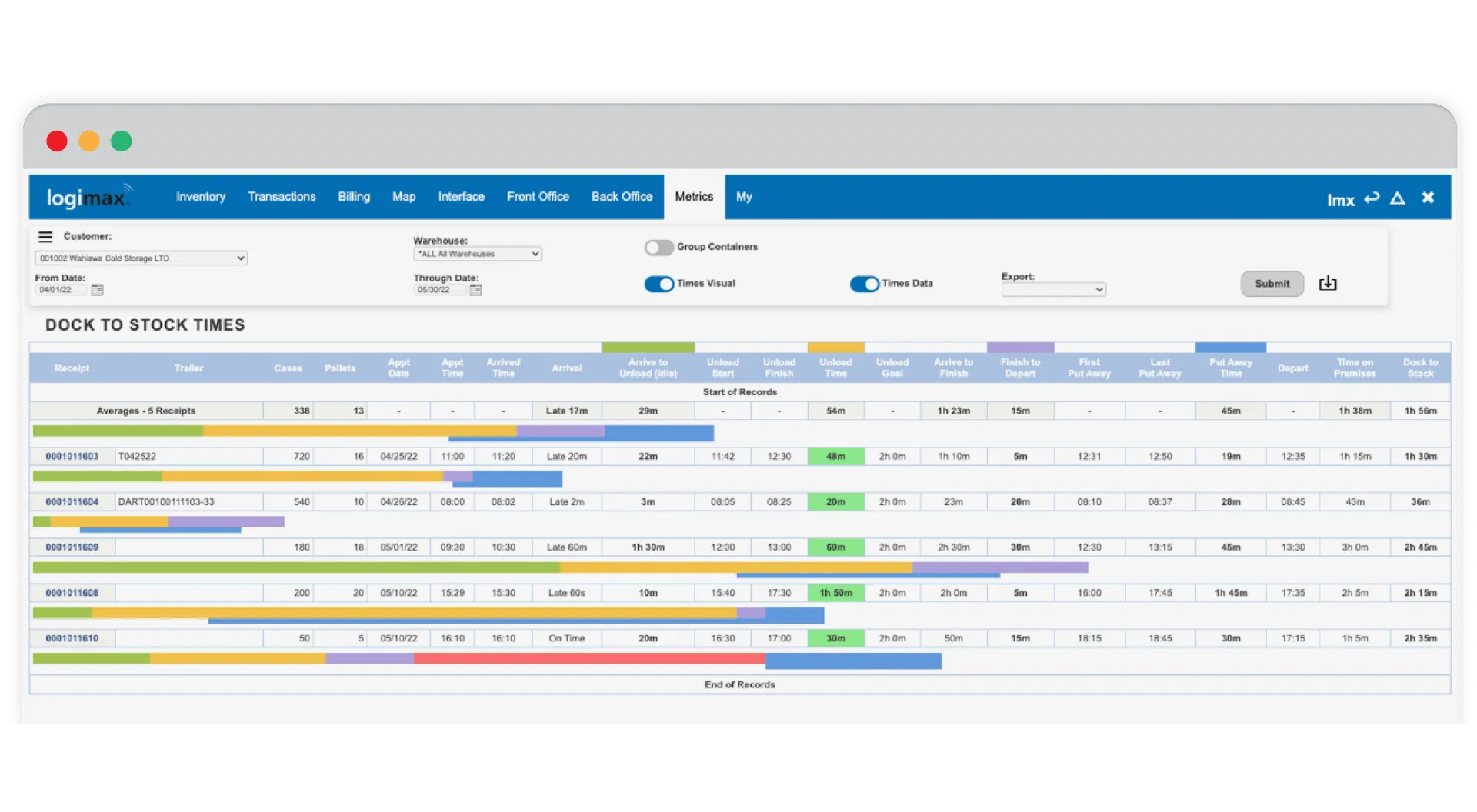

Dock to Stock Reporting

Streamline your warehouse’s efficiency with our Dock to Stock Reporting feature, designed to optimize the movement of goods from receiving to storage. This powerful tool provides real-time visibility into your inventory, ensuring a seamless transition from the dock to the stockroom. By leveraging precise data analytics, you can significantly reduce handling times, minimize errors, and enhance your overall supply chain performance. Empower your team with the insights needed to make informed decisions, elevating your warehouse operations to new heights of productivity and reliability.

Real-Time Putaway Tracking

Gain immediate visibility into the putaway process with Logimax’s real-time tracking. Monitor the status of goods as they move from receiving to storage, ensuring accuracy and timely updates. This feature provides a transparent view of the entire putaway process, enabling quick decision-making and proactive management, vital for maintaining seamless operations.

Customizable Putaway Rules

Tailor putaway rules to align with your specific business needs and warehouse putaway strategy. Logimax’s flexibility ensures that the putaway process is optimized for your unique operational challenges. Define rules based on product characteristics, storage requirements, or other criteria, enhancing control, efficiency, and adaptability in the putaway process.

Automated Putaway Workflow

Automate the entire putaway process with Logimax’s WMS, reducing manual intervention and errors. Streamline operations and ensure consistency across the warehouse with predefined workflows that adapt to various scenarios. This feature saves time, reduces costs, and enhances the accuracy of the putaway process, contributing to a more efficient warehouse environment.

Serial Number and Lot Control

Ensure complete traceability and compliance in the putaway process with serial number and lot control. Maintain accurate records and quickly locate items when needed, enhancing safety and accountability. This feature supports quality assurance and regulatory compliance, providing detailed tracking and reporting capabilities for the putaway process.

Temperature-Controlled Putaway

Manage temperature-sensitive goods with precision using Logimax’s temperature-controlled putaway feature. Ensure products are handled and stored according to specific temperature requirements, maintaining quality and compliance. This specialized solution caters to industries like food and pharmaceuticals, providing accurate temperature monitoring and control during the putaway process.

Visual Map Configuration for Putaway

Utilize visual map configuration for intelligent decision-making in the putaway process. Logimax’s graphical representation of warehouse layout aids in space optimization and strategic planning. By offering a clear view of storage availability and utilization, this feature supports directed putaway strategies, enhancing efficiency, and reducing operational costs.