Warehouse receiving sets the stage for operational success in logistics. This article outlines critical tactics and tools that can transform your receiving department into a model of efficiency and reliability. With these insights, you can elevate your inventory accuracy and streamline your procedures, ensuring your warehouse is prepared to meet the demands of an ever-shifting supply chain.

Key Takeaways

- Efficient warehouse receiving is crucial for supply chain proficiency, directly affecting inventory costs, safety, and customer satisfaction. It involves coordination, communication, and technology to manage the accurate delivery and storage of products.

- Streamlining the warehouse receiving process, which includes pre-receiving preparation, efficient unloading techniques, and thorough inventory inspection, can significantly enhance operational efficiency and cost-effectiveness, reduce errors, and improve inventory management.

- Leveraging advanced Warehouse Management Systems (WMS), automated technologies, and employing continuous employee training can improve real-time inventory tracking, reduce manual errors, and adapt to shifting business demands.

Understanding Warehouse Receiving

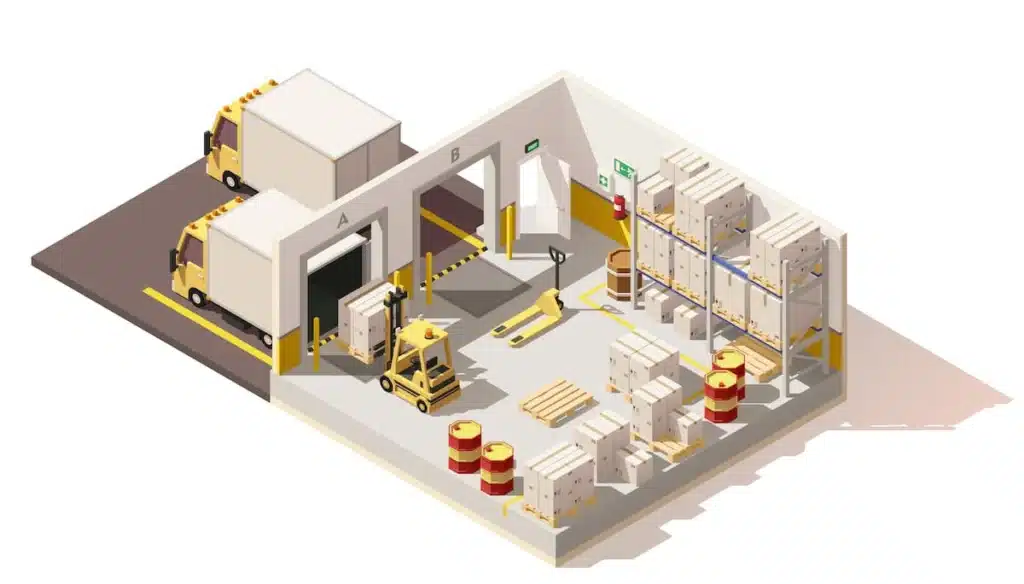

Warehouse receiving is a core function of a proficient supply chain. It’s the process that ensures the correct products are received at the right time, in the right quantities, and in excellent condition. It’s much more than just unloading and storing inventory. Improved customer satisfaction, reduced inventory costs, and enhanced safety are the results of a well-managed warehouse receiving process, which also boosts accuracy and efficiency in stock tracking.

Several crucial procedures are involved in the warehouse receiving process, ensuring accurate delivery and secure storage of commodities. These include the placement of orders, landing of orders at the receiving dock, and the necessary quantity and quality checks – all integral to the warehouse receiving procedure. To track product movement and guarantee precise customer delivery, it’s vital to capture all necessary information during the inbound stage.

The Role of Warehouse Receiving

One of the pivotal aspects of the warehouse receiving process is collaboration with vendors. This collaboration ensures timely deliveries and accuracy in shipments. Every step counts in this partnership. Missteps can lead to a cascade of operational issues, from inaccurate inventory counts to delayed order fulfillment.

Additionally, effective communication within the warehouse receiving team is a necessity. A clear understanding of roles and responsibilities ensures operational efficiency and safety, ultimately leading to higher levels of customer satisfaction. After all, a team that communicates well works well.

Key Components of Warehouse Receiving

Having understood the role of warehouse receiving, it’s time to explore its key components. Like a well-oiled machine, every part has its function. Efficient unloading, facilitated by the use of heavy lifting equipment like forklifts and pallet jacks, is the first component. Digital warehouse software can recommend the optimal allocation of workers and equipment for unloading, improving efficiency based on shipment size and volume.

Upon unloading the cargo, a detailed inspection is conducted to categorize inventory by various factors, ensuring precise processing of goods before delivery to storage. Documentation processes, including receiving and shipping documents, are crucial for matching inventory with purchase orders and avoiding errors.

Ultimately, the key lies in organizing and efficiently storing new inventory. Employing putaway optimization algorithms in operating software contributes to an efficient storage process and stronger efficient inventory storage system, ensuring proper inventory management.

Implementing a Streamlined Warehouse Receiving Process

A streamlined warehouse receiving process paves the way for a smooth and efficient journey, much like a well-paved highway. An efficient receiving process improves cost-efficiency and productivity of the inventory system. On the other hand, a disorganized warehouse receiving process can give rise to stock control issues. Additionally, it may also result in increased operational costs..

The significance of having a consistent approach to receiving includes:

- Ensuring that every team member knows their role, reducing the chances of errors and oversights.

- A robust warehouse receiving process is crucial for efficient inventory management.

- Keeping fulfillment processes cost-effective.

- Enhancing overall efficiency.

Pre-Receiving Preparation

The first step towards a smooth warehouse receiving process is pre-receiving preparation. It’s like prepping your kitchen before cooking a meal. You need to have all your ingredients in place and know the recipe to whip up a great dish. A key aspect of pre-receiving planning is coordinating with suppliers to ensure the warehouse is prepared for incoming shipments.

Creating warehouse receiving order labels with encoded details for easy scanning is another crucial pre-receiving task. Moreover, preparing the warehouse for incoming shipments involves clearing dock space and setting up temporary holding zones. Conducting visual checks and documentation verification before unloading can prevent accepting damaged goods or incorrect shipments.

Efficient Unloading Techniques

The warehouse receiving process’s next vital step is efficient unloading, which sets the foundation for subsequent warehouse operations. Proper allocation of employees and machinery like pallet jacks and forklifts is essential for optimized unloading of shipments. A streamlined warehouse receiving process that minimizes the handling of items leads to greater efficiency in unloading.

To prevent inaccurate records or goods loss, it is critical to implement protocols or a checklist for unloading shipments. It’s like a safety net that ensures every step of the unloading process is handled with precision and diligence.

Thorough Inventory Inspection

Following unloading, the inventory undergoes a rigorous inspection process. Inspection as per quality control measures ensures all received items match the warehouse receiving order, playing a critical role in maintaining stock accuracy. Documenting any damaged items or discrepancies in the warehouse software’s QA module is crucial for error prevention and future reference.

Implementing quality control protocols like random sample inspections can preemptively address issues, reducing the likelihood of customer complaints or returns due to defective products. A well-designed receiving area minimizes the chance of product damage and contributes to the fluidity of materials through the department and into storage.

Read more: Shipping And Receiving Process Workflow: A Comprehensive Guide

Leveraging Technology for Warehouse Receiving

In today’s digital era, warehouse receiving significantly benefits from technology. Warehouse Management Systems (WMS) like Logimax WMS contribute to streamlining warehouse receiving by reducing picking errors, managing inventory in real-time, and helping fulfill orders faster. Automated conveyor systems, robotic unloaders, and sorting solutions can handle goods with minimal human intervention, significantly reducing manual errors and enhancing unloading and sorting efficiency in the receiving process.

From the moment goods are received, accurate records and efficient processing are ensured thanks to technologies like barcode scanners, RFID systems, and emergent systems such as automated pallet management, which facilitate precise tracking and management of inventory. This accurate and real-time tracking of inventory helps in reducing inaccurate or lost inventory and ensuring accurate stock counts.

Warehouse Management Systems (WMS)

At the core of modern warehouse operations are warehouse management systems. They automate tasks such as inventory updates when orders are received and facilitate the verification of documentation, helping to streamline the warehouse receiving process. The use of WMS software can lead to significant cost savings and boost worker productivity by optimizing item placement and selection as part of an efficient warehouse receiving process.

WMS software enables warehouses to:

- Adapt to changing business needs more effectively.

- Ensure continual improvement in operational efficiency.

- Provide shared forecasting and inventory information.

- Facilitate the synchronization of warehouse efficiency with production planning and procurement.

Advanced analytics from a WMS can assist warehouse managers in identifying specific problem areas that require attention, supporting better decision-making for enhanced throughput and profitability.

Barcode Scanners and Labeling Systems

With the advent of barcode scanners and labeling systems, the warehouse receiving process underwent a revolution. Detailed barcodes on shipments can facilitate quicker scanning and verification, enhancing the receiving module of warehouse software. Utilizing barcode scanners during the inventory count significantly accelerates the unloading process while decreasing the likelihood of human error.

Warehouse Receiving Order (WRO) labels with barcodes are critical for quick scanning and checking with warehouse management software, ensuring the integrity of the receiving process. It’s like a secret language that only your warehouse management system can understand and process efficiently.

Real-Time Inventory Tracking

Real-time tracking of inventory has been a game-changer for warehouse management. Real-time inventory tracking, facilitated by warehouse management systems, can significantly reduce lost inventory by assigning specific slots for items and monitoring them from receiving to shipping. These systems contribute to supply chain optimization by providing the visibility needed to adjust inventory levels to their ideal amounts.

By allowing for quicker anticipation of demand changes, an effective WMS can also reduce the need for emergency deliveries. Cloud-based warehouse management systems enable stakeholders to access critical inventory status information from any location using various devices. Real-time data provided by such systems are crucial for tracking Key Performance Indicators and maintaining agility in warehouse management.

Training and Empowering Your Warehouse Staff

The backbone of your warehouse operations is your warehouse personnel. Training and empowering them is vital to ensure the efficiency and accuracy of the warehouse receiving process. Here are several key aspects of an optimal warehouse training strategy:

Ongoing Training Programs

Maintaining operational efficiency, enhancing safety, and adapting to industry changes necessitate ongoing employee training in warehouses. Continuous training programs are essential to keep warehouse staff up-to-date on the latest best practices and technologies, making jobs more attractive and ensuring safe and effective task performance.

Regular training sessions, workshops, or webinars focusing on safety protocols and technology usage can keep the warehouse team updated. It’s like a continuous learning process that helps your team stay on top of their game.

Clear Communication and Expectations

Much like a well-tuned orchestra, clear communication within the warehouse team is crucial. It ensures everyone understands their objectives within warehouse operations. Streamlined operations and minimized misunderstandings result from clear communication, which is vital for an effective workflow.

Encouraging Accountability and Ownership

Improved efficiency and reduced errors can result from promoting accountability and ownership among warehouse employees. Empowering warehouse staff and delegating tasks appropriately can lead to stronger accountability and a sense of ownership among team members. Leadership by example is essential in fostering a culture of accountability in warehouse operations, where standards are applied fairly and consistently. To put it simply, strive to create a team of leaders who take pride in their work.

Monitoring and Improving Warehouse Receiving Performance

Much like a health check-up for your warehouse operations, monitoring and improving warehouse receiving performance is vital. A proper warehouse receiving process facilitates the monitoring of important distribution metrics from one central dashboard.

Pinpointing inefficiencies and identifying areas for refinement to optimize your warehouse receiving process require regular audits.

Tracking Key Performance Indicators (KPIs)

The effectiveness of warehouse operations can be numerically measured using Key Performance Indicators (KPIs). They provide baselines for monitoring performance and the impact of process improvements. Key KPIs for warehouse receiving include receiving efficiency, cost of receiving per line, and receiving cycle time, which are widely tracked to measure operational efficiency.

Receiving efficiency is measured by the volume of inventory a warehouse can receive per staff hour, while the cost of receiving per line reflects the total expense incurred for each product line received, including inventory and logistics expenses. Receiving cycle time is assessed by the average time span from the receipt of stock to its storage, shaping the warehouse’s throughput rates.

Regular Audits and Inspections

Regular audits and inspections are essential. They help detect inventory discrepancies early and maintain high standards in warehouse operations.

Conducting periodic inventory audits helps to detect inventory discrepancies and inventory imbalances early, supporting the planning for subsequent receiving activities.

Adapting to Changing Business Needs

In a fast-paced business environment, it’s necessary to adapt to changing business needs. Flexibility in the warehouse receiving process is crucial to effectively handle varying inventory volumes which can fluctuate due to changing business demands.

Transform Your Warehouse Receiving with Logimax WMS

Optimize your warehouse receiving process with Logimax’s Warehouse Management Software (WMS), designed for efficiency, accuracy, and compliance across all your warehouse operations. Our solution brings a suite of features that cater specifically to the challenges of warehouse receiving, while also enhancing the overall operational workflow.

Key Features and Benefits:

- Real-Time Inventory Tracking: Gain instant visibility with full barcode tracking and handheld processing, ensuring every item’s status is accurately logged and accessible, reducing errors and enhancing decision-making.

- Serial Number and Lot Recall Management: Maintain impeccable traceability and compliance with easy tracking of products by serial numbers and detailed lot recall histories, ensuring safety and accountability.

- Hold/Release/Damage Management: Navigate unexpected scenarios with our comprehensive system, providing the flexibility to efficiently manage inventory statuses, keeping your operations smooth and adaptable.

- Detailed Analytics: Leverage full history tracking by item, location, user, and activity for deep insights into your operations, enabling data-driven decisions that optimize receiving efficiency and identify opportunities for improvement.

- Warehouse Transfers and Cross-Docking: Facilitate seamless goods movement within multi-warehouse operations and minimize handling time with efficient cross-docking, enhancing speed and reducing storage costs.

- Configurable Receiving Workflow: Tailor the receiving process to your specific needs, ensuring critical data is captured accurately and processes are streamlined for maximum efficiency.

The Logimax Advantage:

- Adaptability: Our WMS is built to support diverse industries, from 3PL to manufacturing, cold storage, and retail, ensuring that your warehouse’s unique needs are met.

- Innovation: Logimax is at the forefront of warehouse management technology, continuously evolving to meet future challenges.

- Reliability: With decades of experience and a robust infrastructure, Logimax offers a proven solution that warehouses worldwide trust.

Summary

In conclusion, the warehouse receiving process is a crucial aspect of the supply chain that, when optimized, can lead to improved operational efficiency, customer satisfaction, and reduced costs. Leveraging technology, empowering the warehouse staff, and implementing a robust warehouse receiving process can significantly improve warehouse operations.

Ready to Elevate Your Warehouse Operations?

Contact Logimax today to explore how our Warehouse Management Software can transform your receiving process and beyond. Schedule a demo to witness firsthand the power of Logimax WMS and take the first step towards operational excellence.

Frequently Asked Questions

What is receiving in a warehouse?

Receiving in a warehouse is the process of replenishing stocked inventory and is the first step in delivering an order to a customer. It involves delivering, unloading, and storing ecommerce inventory in a warehouse or fulfillment center.

What is the delivery process in a warehouse?

The delivery process in a warehouse involves aggregating and managing order information, picking, packing, weighing, choosing a carrier, labeling, and finally shipping the order.

What to do when receiving stock?

When receiving stock, it is important to check the shipment against the purchase order, count the items if necessary, record the quantity and condition of the items, and check for any damaged items. Properly storing the items in the warehouse is also crucial. This will help ensure smooth inventory management and accurate record-keeping.

How can technology improve the warehouse receiving process?

Technology can improve the warehouse receiving process by using Warehouse Management Systems and inventory accounting software to minimize errors, manage inventory in real-time, and expedite order fulfillment. This ultimately leads to a more efficient and organized operation.

Why is staff training important in warehouse receiving?

Staff training is important in warehouse receiving because it keeps the staff updated on industry best practices and technological advancements, ensuring efficiency and accuracy. This helps in enhancing the performance and overall success of the warehouse.