Discover the top yard management best practices to streamline operations, maximize efficiency, and minimize costs.

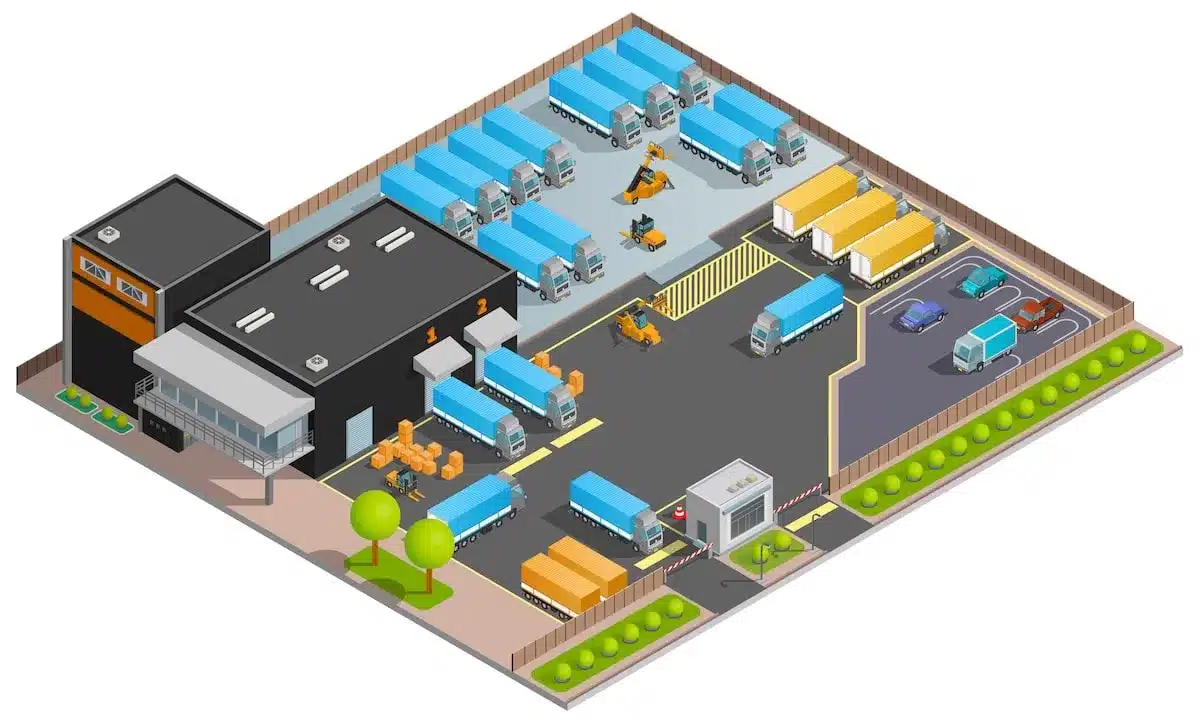

In today’s fast-paced and competitive business environment, effective yard management is crucial for organizations to optimize their supply chain operations. A well-managed yard can streamline processes, improve efficiency, and enhance overall productivity. This article explores various best practices in yard management that can help businesses achieve these goals and stay ahead in the market.

Understanding Yard Management

Yard management is a pivotal component for the seamless operation of supply chain networks. It involves a series of strategic actions and decisions that collectively ensure the efficient handling of goods within a yard or warehouse environment. Let’s delve deeper into each of these critical elements:

Space Allocation:

Effective yard management begins with the strategic allocation of space. This involves more than just maximizing the physical capacity of the yard; it’s about smartly designating specific areas for different activities such as receiving, inspection, storage, and dispatch. This strategic zoning helps in reducing unnecessary movement, speeding up the handling process, and ultimately increasing the throughput of the entire operation.

Inventory Organization:

The organization of inventory is crucial for quick and accurate access to goods. Utilizing digital tools and technologies, such as advanced Warehouse Management Systems (WMS) or Yard Management Systems (YMS), can significantly enhance visibility and control. These systems enable precise tracking of inventory levels, locations, and movements, thereby reducing search times and improving order fulfillment accuracy.

Workflow Optimization:

Streamlining the flow of goods within the yard is essential for minimizing delays and bottlenecks. This involves analyzing and refining processes such as the movement of goods from receiving to storage areas, and then to dispatch. Implementing lean management techniques and continuous process improvement methodologies can lead to more efficient workflows, reducing idle times and increasing overall yard productivity.

Timely Transportation:

Effective coordination with transportation providers is key to ensuring that goods are moved in and out of the yard efficiently. This includes scheduling trucks for loading and unloading, managing dock appointments, and ensuring that transportation resources are optimally utilized. Advanced scheduling tools and real-time communication can help in synchronizing yard activities with transportation schedules, thereby reducing wait times and avoiding costly delays.

By thoroughly understanding and effectively managing these aspects, businesses can lay a strong foundation for successful yard management strategies. This not only streamlines operations but also contributes significantly to the overall efficiency and effectiveness of the supply chain.

For more information on yard management, read our full article: Yard Management 101: Introduction and Best Practices

Yard Management Best Practices:

Successful yard management relies on several crucial components that work together to create a highly efficient operation. By focusing on these components, businesses can improve their yard management practices and achieve better outcomes. Let’s explore each component in detail.

1. Strategic Planning and Layout Design

A well-designed yard layout enhances operational efficiency by minimizing distance traveled and optimizing storage capacity. Strategic planning involves analyzing space utilization, traffic flow, and access points. By carefully planning the layout, businesses can create a streamlined yard environment that supports efficient operations.

2. Implementing a Robust Yard Management System (YMS)

A powerful yard management system is essential for gaining real-time visibility into yard operations. A YMS automates key processes such as trailer management, yard inventory tracking, and gate management. By implementing a robust YMS, businesses can improve efficiency, reduce yard congestion, and enhance overall productivity.

3. Real-Time Asset Tracking and Visibility

Accurate and real-time tracking of assets within the yard is critical for efficient yard management. By leveraging technologies such as RFID and GPS, businesses can gain visibility into the location and status of trailers, containers, and other assets. Real-time tracking ensures that assets are easily accessible, minimizing delays and improving operational responsiveness.

4. Efficient Dock Scheduling and Appointment Management

Efficient dock scheduling and appointment management help optimize the flow of goods in and out of a facility. By implementing a system that allows for advanced scheduling and appointment booking, businesses can reduce waiting times, improve resource allocation, and enhance overall throughput. This ensures that trucks and trailers arrive at the right time, avoiding congestion and delays.

5. Safety Protocols and Compliance

Maintaining a safe working environment is essential for yard management operations. Businesses should establish robust safety protocols, provide adequate training, and ensure compliance with industry regulations. By prioritizing safety, businesses can prevent accidents, reduce downtime, and protect human resources and assets.

6. Communication and Coordination

Effective communication and coordination among all stakeholders are vital for seamless yard management. Clear communication channels, real-time updates, and coordination between drivers, yard personnel, carriers, and other supply chain partners help minimize errors, prevent miscommunication, and ensure smooth workflow.

7. Continuous Training and Skill Development

Investing in the training and skill development of yard management personnel is crucial for driving continuous improvement. By providing regular training sessions, businesses can equip their workforce with the necessary knowledge and skills to handle yard operations efficiently. Continuous learning enhances employee performance, increases job satisfaction, and fosters innovation in yard management practices.

8. Leveraging Data and Analytics for Continuous Improvement

Data plays a vital role in optimizing yard management practices. By leveraging data and analytics, businesses can gain valuable insights into yard operations, identify bottlenecks, and make data-driven decisions. Analyzing key performance indicators (KPIs) such as yard capacity utilization, throughput, and turnaround time helps identify areas for improvement and drive continuous enhancement.

9. Sustainability Practices in Yard Management

Incorporating sustainable practices in yard management not only benefits the environment but also improves operational efficiency. Implementing initiatives such as energy-saving measures, waste reduction, and promoting eco-friendly transportation options can contribute to a greener yard and a more sustainable supply chain.

10. Adapting to Changing Trends and Technologies

In today’s technologically advanced world, it is crucial to stay updated with the latest trends and technologies in yard management. Embracing innovations such as automation, artificial intelligence, and Internet of Things (IoT) can revolutionize yard operations, enhance productivity, and provide a competitive edge in the market.

Conclusion

Effective yard management is essential for optimizing supply chain operations and achieving business success. By implementing best practices such as strategic planning, robust YMS, real-time asset tracking, efficient dock scheduling, and safety protocols, businesses can streamline yard operations and drive operational excellence. Continuous training, leveraging data and analytics, embracing sustainability, and adapting to changing trends further contribute to the success of yard management practices.

Are you looking to enhance your yard management practices? Implementing the right strategies and technologies can unlock the full potential of your supply chain operations. Contact us today to explore how Logimax can help optimize your yard management processes and drive efficiency across your supply chain network.