The inventory turnover ratio measures how often a business sells and replenishes its inventory in a given period. This metric helps gauge the efficiency of inventory management and sales performance. In this article, you’ll learn what the inventory turnover ratio is, why it matters, how to calculate it, and strategies for improvement.

Key Takeaways

- The inventory turnover ratio measures how often a company’s inventory is sold and replaced, indicating the efficiency of inventory management and sales performance.

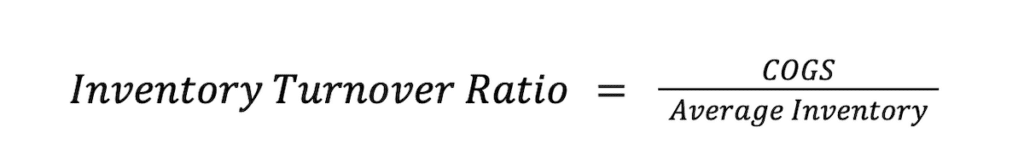

- Calculating the inventory turnover ratio involves dividing the Cost of Goods Sold (COGS) by the average inventory, offering insights into sales performance and operational efficiency.

- Improving inventory turnover can be achieved through strategies like enhancing customer demand, optimizing replenishment processes, and leveraging technology for better inventory tracking.

Understanding Inventory Turnover Ratio

The inventory turnover ratio measures how often a company’s inventory is sold and replaced over a specific period. This metric reveals how efficiently a business manages its stock relative to its sales activities.

A good inventory turnover ratio indicates effective inventory management and strong sales performance, while a low ratio can highlight potential issues with excess inventory and inadequate sales strategies.

What Is the Inventory Turnover Ratio?

The inventory turnover ratio measures how frequently a company sells and replenishes its inventory within a specific period. This metric offers valuable insights into both sales performance and inventory management. For example, a ratio of 2 indicates that the company sold and restocked its entire inventory twice during the given timeframe.

The standard method for calculating inventory turnover involves dividing the Cost of Goods Sold (COGS) by the average inventory value. This calculation is typically done on a quarterly or monthly basis to provide a clear picture of how efficiently inventory is managed.

Why Inventory Turnover Ratio Matters

The inventory turnover ratio reflects overall company health, indicating how well a business manages its product inventory, supply chain efficiency, cash flow, and profitability. Tracking this ratio helps businesses gauge sales performance and plan more effectively.

A higher ratio often signifies efficient sales processes and lower holding costs, leading to better profitability. It provides insights into inventory management strategies, helping refine operations to optimize costs and improve profitability.

Conversely, a low inventory turnover ratio could signal poor sales performance or over-investment in slow-moving products.

Calculating the Inventory Turnover Ratio

The inventory turnover ratio is calculated by dividing the Cost of Goods Sold (COGS) by the average inventory value over a specific period. This formula offers valuable insights into how efficiently a company is managing its inventory. A higher ratio suggests quicker sales and restocking, which generally indicates stronger sales performance and operational efficiency.

For example, if a company has a COGS of $10,000 and an average inventory of $7,500, the inventory turnover ratio would be 1.33.

Formula:

Accurate calculation of this ratio requires reliable data on both COGS and average inventory. It’s important to assess this ratio regularly—typically on a quarterly or monthly basis—for a clearer picture of how well inventory is being managed.

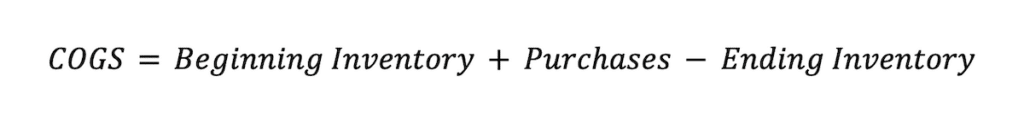

How to Determine Cost of Goods Sold (COGS)

Determining the Cost of Goods Sold (COGS) is crucial for calculating the inventory turnover ratio. COGS covers all direct costs tied to acquiring, manufacturing, or assembling goods, including raw materials, labor, and manufacturing overhead.

To compute COGS, use the following formula:

It’s important to be meticulous when calculating COGS, as mistakes like improper accounting for discounts, returns, or the incorrect application of accounting methods such as FIFO or LIFO can skew results. Accurate COGS calculations ensure a reliable inventory turnover ratio and guide better inventory management decisions.

Calculating Average Inventory

Calculating average inventory smoothes out fluctuations and provides a consistent view of inventory levels over time. This is done by adding the beginning inventory to the ending inventory and then dividing by two.

Averaging inventory values helps businesses even out spikes and dips, leading to a more accurate inventory turnover calculation.

Analyzing Your Inventory Turnover Ratio

Analyzing the inventory turnover ratio is crucial for understanding cost management, sales performance, and workflow optimization. By regularly tracking this metric, businesses can identify inefficiencies and take steps to streamline operations.

Different industries rely on this analysis in various ways. Retailers, for instance, use inventory turnover analysis to adjust seasonal product lines, ensuring popular items are always in stock. Meanwhile, manufacturers leverage turnover data to fine-tune production cycles, minimizing overproduction and reducing holding costs.

Seasonal fluctuations and other factors can significantly impact inventory levels. Calculating average inventory over time allows businesses to account for these variations and make more accurate decisions regarding inventory management.

High Inventory Turnover Ratio

A high inventory turnover ratio typically signals strong sales performance and efficient inventory management. This is particularly beneficial for industries like e-commerce, where inventory that moves quickly reduces holding costs. However, maintaining a high ratio comes with challenges, such as the risk of stockouts, which can result in missed sales opportunities.

While a high turnover ratio is a positive indicator, it’s important to strike a balance. Excessively high turnover may suggest that stock levels are too low to meet demand, potentially limiting sales. Industry benchmarks, such as Walmart’s average ratio of 8.20, provide useful targets and help businesses assess whether they are effectively managing inventory.

Low Inventory Turnover Ratio

A low inventory turnover ratio often signals poor sales performance, excess stock, or outdated products. It suggests that a company may be struggling to sell its products effectively or is holding too much inventory. This can lead to increased holding costs and require additional resources to manage obsolete inventory.

Tracking inventory turnover helps avoid over-investment in slow-moving or obsolete products. Decisions based on inaccurate ratios can lead to overstocking or stockouts, negatively affecting cash flow.

Accurately interpreting inventory turnover ratios helps businesses maintain profitability and operational efficiency.

Ideal Inventory Turnover Ratio

The ideal inventory turnover ratio varies across industries. Retail sectors typically experience higher turnover ratios compared to manufacturing industries due to shorter product lifecycles and quicker sales cycles. Retailers often aim for a ratio between 2 and 4 to align restocking with sales cycles.

In contrast, manufacturers may have optimal ratios closer to 1 due to longer production cycles and the need to maintain raw materials for uninterrupted production. Understanding these industry-specific benchmarks is crucial for setting realistic inventory management goals and optimizing stock levels.

Strategies to Improve Inventory Turnover Ratio

Boosting your inventory turnover ratio requires strategic efforts focused on both sales performance and inventory optimization. Key strategies include increasing customer demand through targeted marketing and promotions, refining your inventory replenishment processes to match sales trends, and leveraging technology to streamline inventory management.

Leverage Supplier Relationships

Strengthening supplier partnerships can improve lead times, making it easier to align stock levels with demand. This helps reduce excess inventory and ensures quicker restocking when sales increase.

Enhance Customer Demand

Enhancing customer demand is vital for improving inventory turnover. Robust marketing efforts can significantly boost sales. Offering promotions and discounts can incentivize purchases, leading to better turnover. Creating a positive shopping environment and leveraging multiple sales channels can attract more customers and increase sales.

Providing superior customer experiences, such as faster delivery and convenient shopping options, can further enhance demand. In today’s marketplace, consumers increasingly prioritize convenience and speed, making it essential for businesses to adapt and offer competitive advantages to meet customer demand and improve inventory turnover.

Optimize Inventory Replenishment

Optimizing inventory replenishment is crucial for maintaining a good turnover ratio. Effective inventory forecasts and adjusting order quantities based on sales trends can streamline reordering and reduce excess inventory risk. Automating replenishment can further enhance efficiency by minimizing human error and ensuring timely stock updates.

Separating long-term from short-term storage improves replenishment efficiency and enhances the facility’s overall turnover ratio. Manufacturers need to balance production cycles with inventory management to prevent excess stock or stockouts, ultimately improving turnover.

Implement Just-in-Time (JIT) Inventory Management

Implementing JIT (Just-in-Time) inventory management can significantly improve turnover by aligning inventory levels with demand. JIT reduces storage costs and prevents overbuying, leading to better cash flow and inventory efficiency. Successful retailers manage JIT risks by closely monitoring supply chains and maintaining proactive communications.

Adopting JIT principles enhances responsiveness to market demand and minimizes excess inventory. This approach improves turnover and supports a more streamlined, cost-effective operation, making it a valuable strategy for optimizing inventory management.

Leveraging Technology for Better Inventory Management

Leveraging technology is key to better inventory management and improving the turnover ratio. Solutions like inventory management software and automation tools help businesses track sales and inventory metrics more accurately, streamline processes, and enhance demand forecasting.

These tools provide real-time visibility into inventory levels, enabling better decision-making and more efficient operations.

Inventory Management Software

Effective inventory management software provides real-time visibility into inventory levels and includes analytics tools and data tracking capabilities. Continuous real-time records help businesses adjust stock levels based on customer demand insights, enhancing tracking and ensuring efficient inventory management.

Moreover, inventory management software can be integrated with other systems, like route optimization software, to streamline operations further. Fulfillment solutions often include a warehouse management system (WMS) along with various fulfillment services, helping businesses manage inventory more effectively and improve their turnover ratio.

Streamlining Decision-Making with Automation

Automation tools enhance demand forecasting accuracy and minimize stockouts. By automating order management processes, businesses achieve faster order fulfillment and optimize stock levels. These tools streamline operations, reduce human error, and ensure efficient inventory management, leading to improved turnover ratios.

Incorporating automation tools into inventory management boosts efficiency and supports better decision-making. Precise demand forecasting enabled by automation helps businesses align inventory levels with market demand, reducing excess inventory and improving overall operational efficiency.

Common Pitfalls in Inventory Turnover Calculation

Calculating and interpreting inventory turnover ratios can be fraught with pitfalls leading to misguided business decisions. Errors in calculating Cost of Goods Sold (COGS) and misinterpreting inventory data are common issues that can skew the ratio, resulting in inaccurate assessments of inventory efficiency and sales performance.

Errors in COGS Calculation

Mistakes in calculating COGS can significantly distort the inventory turnover ratio, leading to incorrect business strategies. Common errors include improper accounting for discounts, returns, and freight costs, as well as mistakes in applying accounting methods like FIFO or LIFO. These inaccuracies can adversely impact product pricing, order amounts, and sales forecasts.

Omitting certain direct costs or miscounting inventory can also lead to incorrect COGS calculations. Ensuring accuracy in COGS calculation is critical for obtaining a precise inventory turnover ratio, which in turn, guides better inventory management and operational efficiency.

Misinterpreting Inventory Data

Misinterpreting inventory data can lead to inaccurate assessments of sales performance and inventory efficiency. Understanding the relationship between sales, inventory levels, and product returns is crucial to avoid misinterpretation. For instance, high product return rates can negatively impact both sales and inventory, leading to miscalculations in turnover ratios.

Accurate interpretation of inventory data ensures that businesses make informed decisions based on reliable inventory turnover ratios. This helps avoid overstocking or stockouts and supports effective inventory management strategies that enhance profitability and operational efficiency.

Real-World Examples of Inventory Turnover Analysis

Real-world examples of inventory turnover ratios provide valuable insights into how businesses can apply theoretical concepts to improve their operations. By examining case studies from different sectors, such as retail and manufacturing, businesses can understand the practical applications and challenges of managing inventory turnover.

Case Study: Retail Industry

In the retail industry, a high inventory turnover ratio suggests that products are sold quickly, indicating effective inventory management and strong sales performance. For example, home improvement retailers have observed a significant year-over-year increase in inventory levels, approximately 16% since 2018. Understanding these factors helps retailers enhance inventory efficiency and optimize management strategies.

Walmart, one of the leading retailers, refreshed its stock every 42 days in fiscal year 2022, showcasing its ability to manage inventory effectively and maintain a high turnover ratio. These practices highlight the importance of efficient inventory management in achieving strong sales performance and customer satisfaction.

A Closer Look: Manufacturing Sector

In the manufacturing sector, the inventory turnover ratio is critical for indicating how efficiently a company produces and sells its products while managing inventory levels. High inventory turnover ratios suggest better production efficiency, reduced holding costs, and improved cash flow. Manufacturers can achieve favorable inventory turnover by aligning production schedules closely with market demand.

Implementing Just-in-Time (JIT) inventory management can streamline operations and enhance inventory turnover by reducing excess stock and improving responsiveness. Effective forecasting and demand planning are essential practices to enhance inventory turnover, ensuring that manufacturers produce only what is needed to meet market demand and avoid overstocking.

How Logimax Can Help Improve Your Inventory Turnover

Logimax’s Warehouse Management System (WMS) is designed to help businesses optimize inventory turnover by providing real-time visibility, automated replenishment, and data-driven insights.

- Real-Time Visibility: With real time inventory tracking, Logimax ensures that you always know what’s in stock, helping prevent overstocking and reducing holding costs.

- Automated Replenishment: Our WMS analyzes demand and sales patterns to automate restocking, minimizing stockouts and excess inventory while improving cash flow.

- Advanced Analytics: Logimax offers powerful reporting tools that track inventory turnover ratios, providing actionable insights to optimize stock levels and operational efficiency.

- Seamless ERP Integration: Our system integrates with your existing ERP, ensuring smooth data flow across procurement, sales, and operations for better decision-making.

Ready to boost your inventory turnover? Contact us today to learn how Logimax can help you achieve greater efficiency and profitability.

Summary

Mastering the inventory turnover ratio is crucial for any business looking to optimize its inventory management, improve sales performance, and enhance profitability. By understanding, calculating, and analyzing this ratio, businesses can gain valuable insights into their inventory efficiency and make informed decisions to streamline their operations. Implementing strategies such as enhancing customer demand, optimizing inventory replenishment, and leveraging technology can significantly improve inventory turnover ratios.

The journey to mastering the inventory turnover ratio requires continuous effort and adaptation. By avoiding common pitfalls and applying best practices, businesses can achieve a balanced and efficient inventory management system that supports sustained growth and profitability. Embrace these strategies and let the inventory turnover ratio be your guide to a more successful and efficient business operation.

Ready to optimize your inventory turnover? Contact Logimax today to learn how our WMS solutions can help you streamline your operations and improve profitability.

Frequently Asked Questions

What does an inventory turnover ratio of 12 mean?

An inventory turnover ratio of 12 means you’re selling and replacing your entire stock every month, which is a great sign of strong sales and effective inventory management. It shows your products are in demand and that you’re keeping your stock fresh.

What does an inventory turnover ratio of 5 mean?

A turnover ratio of 5 means you’re cycling through and replacing your entire stock five times a year. This is typically a good sign of efficient inventory management, indicating that your products are in demand and you’re not overstocking.

How do you calculate the inventory turnover?

To calculate inventory turnover, divide your Cost of Goods Sold (COGS) by your average inventory value. A higher turnover ratio indicates strong sales performance and efficient inventory management.

What is a good inventory turnover ratio?

A good inventory turnover ratio usually falls between 2 and 4, depending on your industry. Retailers may aim for a higher ratio due to fast-moving goods, while manufacturers with longer production cycles may see a lower ratio but still maintain efficiency by aligning production with demand.