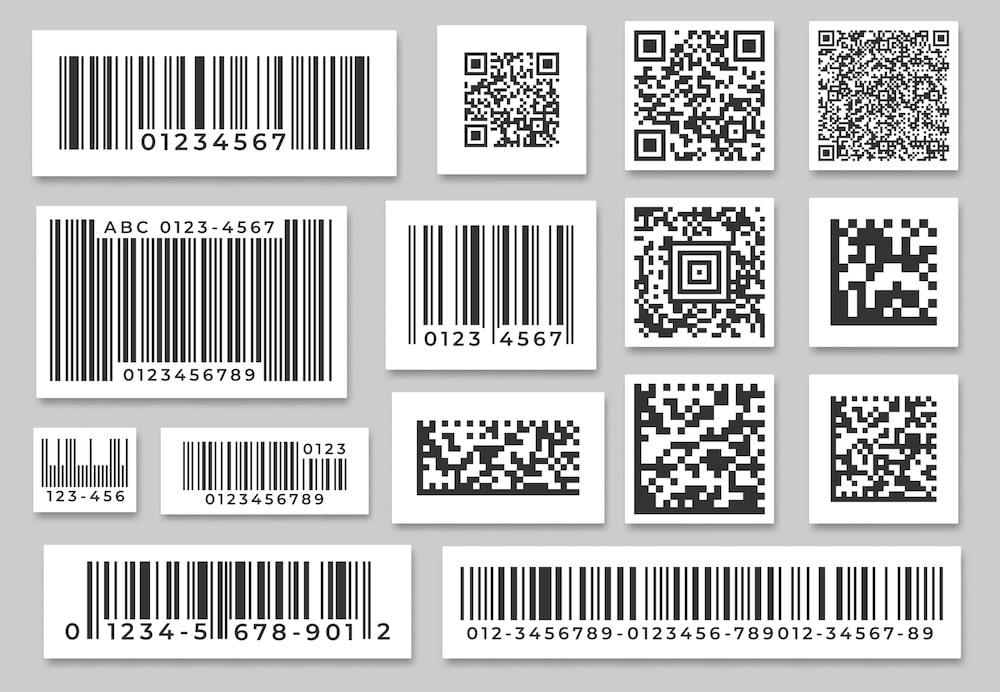

Discover the differences between 1D and 2D barcodes in this comprehensive comparison article.

1D vs 2D Barcodes: A Comprehensive Comparison

In today’s digital age, barcodes have become an essential part of our lives, playing a vital role in various industries, from retail to logistics. Barcodes enable businesses to streamline their operations, improve inventory management, and enhance customer service. However, not all barcodes are created equal. There are significant differences between 1D and 2D barcodes that impact their functionality and potential applications. In this article, we will delve into the intricacies of these two barcode types, explore their unique features, and analyze their respective benefits and limitations.

Understanding Barcodes: An Introduction

Before we dive into the comparison, let’s start by understanding what barcodes are and why they are crucial in modern business.

Barcodes are machine-readable representations of data in a visual pattern format. They consist of a series of parallel lines, spaces, and numbers that encode information such as product details, pricing, and inventory numbers. Barcodes act as a universal language that allows businesses to store and retrieve data efficiently and accurately.

What is a Barcode?

At its core, a barcode is a unique sequence of characters that can be scanned electronically. It serves as a bridge between the physical and digital worlds, enabling seamless data exchange between different systems and processes.

Barcodes provide quick data entry, minimize human error, and simplify the retrieval of information. With a simple scan, businesses can access product details, track inventory, and expedite the checkout process.

The Importance of Barcodes in Modern Business

Barcodes play a vital role in various aspects of modern business operations. They streamline inventory management, improve supply chain efficiency, and enhance customer experience.

By utilizing barcodes, businesses can track their inventory in real-time, ensuring accurate stock levels and preventing stockouts. This enables timely replenishment, minimizing the risk of lost sales and customer dissatisfaction.

Barcodes also facilitate accurate and efficient point-of-sale transactions, allowing businesses to process purchases quickly, reduce waiting times, and enhance the overall customer experience. Additionally, barcodes enable businesses to gather valuable data on consumer preferences, purchasing habits, and product performance, helping them make informed decisions about pricing, promotions, and inventory management.

Moreover, barcodes have revolutionized the logistics industry. With the ability to track packages and shipments using barcodes, businesses can ensure the timely delivery of goods to customers. This not only improves customer satisfaction but also reduces the risk of lost or misplaced shipments.

Furthermore, barcodes have found their way into the healthcare industry, where they are used to improve patient safety and streamline medication administration. By scanning barcodes on medication labels, healthcare professionals can ensure that the right medication is given to the right patient at the right time, reducing the risk of medication errors and improving overall patient care.

In addition to their practical applications, barcodes have also become a part of our everyday lives. From scanning barcodes on grocery items to comparing prices, to using mobile apps that scan QR codes for discounts and promotions, barcodes have become an integral part of our consumer experience.

In conclusion, barcodes are not just a series of lines and numbers; they are a powerful tool that drives efficiency, accuracy, and convenience in modern business. Whether it’s managing inventory, improving supply chain operations, or enhancing customer experience, barcodes continue to play a vital role in shaping the way businesses operate in today’s digital age.

The Basics of 1D Barcodes

Now let’s shift our focus to 1D barcodes, also known as linear barcodes, which are the traditional and most commonly used type of barcode.

Defining 1D Barcodes

1D barcodes consist of a series of parallel lines and spaces of varying widths. These lines represent data in a one-dimensional format, encoding information by the variation in their thickness and spacing.

Each 1D barcode has a specific symbology, such as UPC, EAN, or Code 39, which determines the structure and composition of the barcode and the type of data it can encode. 1D barcodes are primarily used to represent numerical or alphanumeric data in a linear format.

The Structure of 1D Barcodes

1D barcodes typically consist of a start character, data characters, a check digit, and an end character. The start and end characters serve as indicators for the barcode reader, indicating the beginning and end of the barcode. The data characters contain the encoded information, and the check digit ensures the accuracy of the scanned data.

The start character is like the opening act of a barcode performance, setting the stage for the data characters to shine. It grabs the attention of the barcode reader, signaling that a barcode is about to be scanned. The end character, on the other hand, is like the grand finale, gracefully concluding the barcode’s performance and letting the reader know that the data has been fully captured.

Read more: The Essential Guide to ID Barcode Technology

Common Uses of 1D Barcodes

1D barcodes are widely used in various industries and applications. They can be found on product packaging, price tags, shipping labels, and even tickets. 1D barcodes are ideal for situations where simplicity and compatibility are crucial, such as in retail environments.

With a single scan, 1D barcodes provide instant access to product information, pricing, and inventory data. Retailers can quickly scan items at the point of sale, update stock levels, and manage pricing. Additionally, 1D barcodes can be utilized for other purposes, such as encoding patient information in healthcare settings or tracking assets in logistics and warehousing.

Imagine a bustling retail store, with customers eagerly browsing through the aisles. Each product on the shelves proudly displays its own unique 1D barcode, ready to be scanned and reveal its secrets. The barcode scanner swiftly glides over the barcode, capturing the encoded data and instantly updating the store’s inventory system. This seamless process ensures that the store always has accurate stock levels and can efficiently manage its supply chain.

In the healthcare industry, 1D barcodes play a vital role in patient safety and information management. By encoding patient details, such as medical history or allergies, into a barcode, healthcare professionals can quickly access critical information at the point of care. This ensures that the right treatment is administered to the right patient, reducing the risk of errors and improving overall patient outcomes.

Delving into 2D Barcodes

Now, let’s explore the world of 2D barcodes, which have gained significant popularity and recognition in recent years.

What are 2D Barcodes?

Unlike 1D barcodes, which represent data in a linear format, 2D barcodes encode information in both horizontal and vertical dimensions, allowing for a higher density of data storage. 2D barcodes appear as square or rectangular patterns, consisting of black and white modules arranged in a grid-like structure.

2D barcodes can encode a broader range of data types, including text, numbers, symbols, and even binary data. This increased data capacity makes 2D barcodes suitable for more complex applications that require storing and transmitting large amounts of data within a relatively small space.

How 2D Barcodes Work

2D barcodes utilize advanced encoding techniques, such as matrix codes, QR codes, or Data Matrix codes, to store and retrieve data. These encoding methods use patterns of modules that can be recognized and decoded by specialized barcode scanners or smartphone applications.

Unlike 1D barcodes, which require a linear scanning motion, 2D barcodes can be scanned from any orientation or angle. This versatility enhances scanning efficiency and allows for seamless integration into various devices and applications.

Typical Applications of 2D Barcodes

2D barcodes cater to a wide range of applications across multiple industries. They are commonly used for mobile ticketing, electronic payment systems, document management, and inventory tracking.

For instance, 2D barcodes are often seen in electronic boarding passes, allowing passengers to simply scan their smartphones instead of physical tickets. In the healthcare industry, 2D barcodes enable accurate patient identification, reduce medication errors, and enhance patient safety. Additionally, 2D barcodes are widely used in supply chain management to track and trace products, enabling efficient inventory management and effective recall processes.

Read more: Complete Guide to Warehouse Barcode Systems

Key Differences Between 1D and 2D Barcodes

Now that we have explored the basics of both barcode types, let’s compare their key differences to help you choose the most suitable barcode for your specific needs.

Data Capacity and Size

One of the significant advantages of 2D barcodes over 1D barcodes is their higher data capacity. 2D barcodes can store significantly more information, allowing for more detailed product descriptions, serial numbers, or website links. Additionally, 2D barcodes are smaller in physical size compared to 1D barcodes, making them ideal for applications with limited space.

Scanning Requirements

While 1D barcodes can be scanned using traditional barcode scanners and laser scanners, 2D barcodes require specialized imaging scanners or smartphone applications that support 2D barcode recognition. This distinction should be taken into consideration when selecting a barcode for your intended use.

Error Correction Capabilities

Another significant difference between 1D and 2D barcodes lies in their error correction capabilities. 2D barcodes incorporate error correction algorithms, allowing for the recovery of missing or damaged data. In contrast, 1D barcodes lack this error correction capability, making them more susceptible to data loss or misinterpretation in case of scanning errors.

Leveraging 1D and 2D Barcodes with Logimax WMS

Logimax’s Warehouse Management Software (WMS) excels in utilizing both 1D and 2D barcodes, enhancing efficiency across multiple industries. Our system optimizes the strengths of each barcode type to streamline operations and improve data management.

Dual Barcode Integration

Our WMS supports both 1D and 2D barcodes, allowing for:

- Comprehensive Data Storage: Use 2D barcodes for complex information like serial numbers and batch data in compact formats.

- Increased Accuracy: Minimize errors with precise scanning, ensuring reliable data capture and improved inventory management.

- Efficient Processes: Enhance tracking and expedite workflows from receiving to shipping, boosting productivity.

Seamless System Compatibility

Logimax WMS integrates seamlessly with existing ERP systems through advanced API and EDI capabilities, ensuring a unified and efficient workflow across your business operations.

Conclusion

Barcodes, whether 1D or 2D, are indispensable tools in the modern digital landscape, enhancing how businesses manage operations, track inventory, and serve customers. Understanding the unique characteristics and applications of each barcode type allows companies to choose the most effective solutions for their specific needs. While 1D barcodes offer simplicity and efficiency for basic data tasks, 2D barcodes provide greater data capacity and flexibility for complex applications.

Take Action

Are you ready to enhance your operational efficiency and data management capabilities? Explore how Logimax’s Warehouse Management Software can integrate and optimize barcode technology within your business. Visit our industry pages for more information or contact us today to schedule a personalized consultation. Harness the full potential of barcode technology and propel your business forward with Logimax.